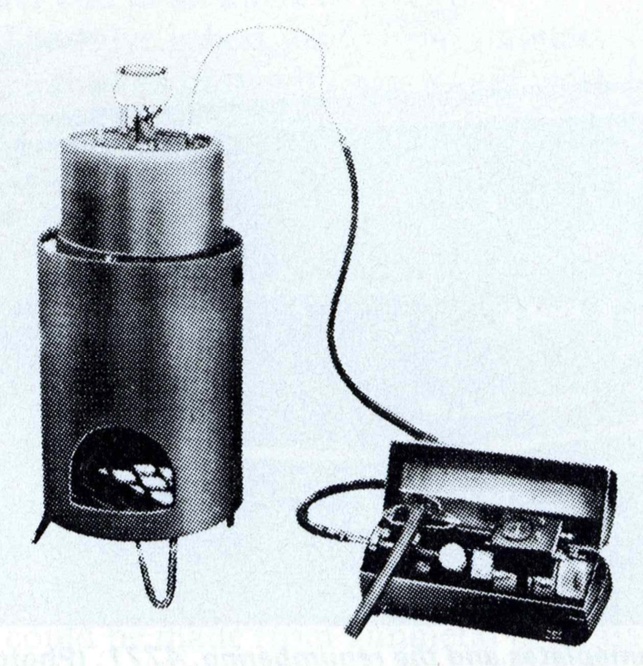

Boiler & Furnace

About the boiler and furnace of the Alco Firefly

The Alco Firefly is designed to nest when packed. The generator set stores in a sheet metal box, which fits inside the boiler vessel along with tools, hoses, and spares. The boiler collapses down into the furnace shell. The three legs of the furnace fold inward. The result is a cylinder that packs inside of a CLE parachute drop container.

Polish paratroopers recover CLE, 1944 (paradata.org.uk)

Polish paratroopers recover CLE, 1944 (paradata.org.uk)

Boiler

Continuing on the theme of drawing from preexisting products to create the Alco Firefly, Ian Bradley got hold of a field service pressure cooker to try as a boiler. (If any readers have a British WWII field service pressure cooker, please write us.)

Bradley’s trial proved that the pressure vessel was up to the task, but the volume was insufficient for the run time required. So he got a second pressure cooker, cut off the bottom from one and the top from the other and welded the larger top and bottom pieces together about the circumerference.

On production boilers, it appears that a single pressure cooker was cut in half for each boiler. The elongation comes from a sheet of steel rolled into a tube. The seam of the tube was welded and the top and bottom pieces of the pressure cooker were welded to the tube with two circumferential welds.

Once his high capacity boiler prototype was completed, Bradley set it upon three bricks outside of his home workshop and tested it. It produced steam for over two and a half hours, long enough to be considered practical.

Furnace Variations

There were at least four versions of the furnace. The design appears to have been simplified to reduce the number of sheet metal parts. Finally, to save weight, the furnace shell was replaced with a tripod to raise the boiler over an open fire, much like the three bricks Ian Bradley used to test his prototype boiler.

Sliding Door

I purchased this from Hindman Auctions, Chicago, Illinois, USA

I purchased this from Hindman Auctions, Chicago, Illinois, USA

Drawings for this furnace, based on the one pictured above are available on the resources page.

Hinged Door

Photo by Jan Bus (via campx.ca) from exhibit at d’Olde Mesiene in Genemuiden, Netherlands

Photo by Jan Bus (via campx.ca) from exhibit at d’Olde Mesiene in Genemuiden, Netherlands

No Door

Originally from Arthur Lyon & Co. Catalogue

Originally from Arthur Lyon & Co. Catalogue

Tripod

From Preston Services

From Preston Services